SABO Industrial designs and manufactures all our equipment with the highest quality materials right here in our Newburgh, New York facility. All of our space saving wastewater treatment equipment is built to last. We strive for the highest quality, and build each machine to provide consistent, effective operation at all times. Our equipment is easy to use and requires very little maintenance.

In this video see the custom designed treatment system SABO Industrial created for a public transit system.

We are proud of the SABO product and fully stand behind our work.

Everclean Series of Batch Units

Designed for clients with smaller volumes and potentially inconsistent waste streams, the Everclean series of manual batch processors are available in 100-gallon, 250-gallon and 500-gallon capacities.

EV100 - Everclean 4 Bag Filter

100 Gallon Batch Unit

- #304 Stainless Steel Satin Finish

- 4 Bag Filters

- Storage Tank

- Emergency Stop

- 48″W x 60″L

- 110V, Single Phase, 60 Hz.

EV250 - 250 Gallon Mix Tank

250 Gallon Mix Tank

- #304 Stainless Steel Satin Finish

- Emergency Stop

- 40″W x 48″L

- 110V, Single Phase, 60 Hz.

Separate bag filter tank may be required.

EV500 - 500 Gallon Mix Tank

500 Gallon Mix Tank

- #304 Stainless Steel Satin Finish

- Emergency Stop

- 51″W x 68″L

- 110V, Single Phase, 60 Hz.

- 20 AMP Dedicated GFI Circuit Required

Separate bag filter tank may be required.

EconoFlow Series of Flow Through Units

Designed for clients with higher volumes and consistent waste streams, the EconoFlow series are continuous-flow systems that are available in 5, 10 or 25-gallons per minute capacities.

EC510 - EconoFlow 16 Bag Filters

Can be set to run at 5 or 10 Gallons Per Minute

- #304 Stainless Steel Satin Finish

- 5 Gallons Per Minute

- 16 Bag Filters

- Storage Tank

- Emergency Stop

- 48″W x 96″L

- 220V, Single Phase, 60 Hz.

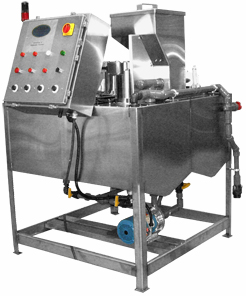

EC10 - EconoFlow 10

10 Gallons Per Minute

Designed with a smaller footprint

- #304 Stainless Steel

- 3 Mix Chamber

- 50 lb. Capacity Separating Agent

Feed Hopper with Speed Control

and Vibrator - Emergency Stop

- 48″W x 48″L

- 220V, Single Phase, 60 Hz.

- 20 AMP Dedicated GFI Circuit Required

Optional Upgrades (Photo Represents EC10 with Upgrades):

- 3 Stainless Steel Variable Speed

Mix Motors - Low Powder Sensor

- NEMA4X Electrical Box

- Flow Meter

- Tower Light / Audible Alarm

- Mix Chamber Washdown Plumbing

Assembly

Bag filter tank not included.

EC25DBF - EconoFlow

25 Gallons Per Minute

Deep Bed Filter

- #304 Stainless Steel Satin Finish

- 25 Gallons Per Minute

- Self indexing dewatering table

- Storage Tank

- 144″W x 48″L

- 220V, Single Phase, 60 Hz.

- 30 AMP Dedicated GFI Circuit Required

The Bag Filter Tanks

The bag tanks are used in conjunction with the EC10, EV250 & EV500 for filtering the treated effluent. They can also be used as a pre-filtering source for clients with existing equipment requiring removal of excessive solids.

BFT16 - 16 Bag Filter Tank

- #304 Stainless Steel Satin Finish

- 4 Independently-Operated Bag Filter Manifolds

- 40″W x48″L

- 110V, Single Phase, 60 Hz.

- 20 AMP Dedicated GFI Circuit Required

BFT24 - 24 Bag Filter Tank

- #304 Stainless Steel Satin Finish

- 6 Independently-Operated Bag Filter Manifolds

- 48″W x 78″L

- 110V, Single Phase, 60 Hz.

- 20 AMP Dedicated GFI Circuit Required

Custom Batch Systems

SABO specializes in designing systems to meet a client’s particular needs, such as space requirements, secondary containment needs and automation.

Custom Batch System consists of:

- 250 Gallon Batch Unit

- Bag Filter Tank

- Stainless Steel Single Stage Housing

- Granulated Activated Carbon Vessel

- Secondary Containment Unit

- Double Wall Storage Tank

Features Include:

- #304 Stainless Steel Satin Finish

- Emergency Stop

- 48″W x 60″L

- 110V, Single Phase, 60 Hz.